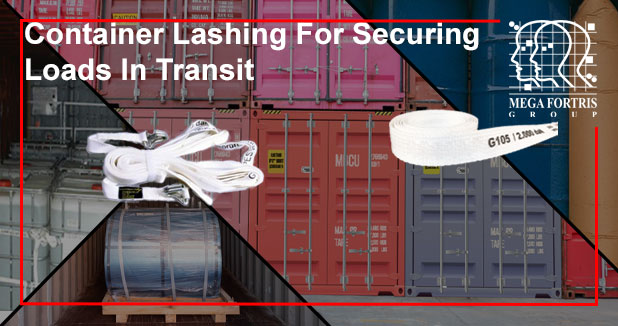

Container lashing is a fast and effective load securing method that fulfils multiple requirements for securing goods against damage in transit. Container lashing is used due to its versatility for different applications and ease of use in securing different sized objects in containers. Our lashing straps can be used to secures goods in two ways. The first is to secure cargo inside the container to eliminate movement and damage of the goods, the second is to secure the cargo to stop goods moving backwards in transit and removing falling hazards when unloading. Container lashing is also effective at dealing with high load weights, by using 2 or 4 or more lashing points within the container load strain can be efficiently spread between all points heightening the systems strength overall. Therefore, when these container lashing systems are applied correctly utilising the required amount of lashing points, this solution is ideal for heavy cargo such as chemicals, IBC Containers, heavy metals such as steel or shipments from the oil and gas industry such as drums and more.

Container lashing types and systems

Woven lashing 2-point belt systems

This lashing system is fast to apply, efficient and allows woven lashing to replace ratchet systems, wire rope, chains and complex expensive wooden blocking and bracing. Advantages of woven lashing are that it can offer linear strengths up to 5000daN with different widths of the lashing from 32mm – 40mm. lashing is used in conjunction with heavy duty buckles to assure high system strength and fast delivery when anchored to the application or container. Our woven lashing is certified by DNV GL for load restraint assemblies so is assured to secure your cargo above the break strength requirements for each size of lashing. This system utilises two lashing points one on each side and can be applied to a wide range of items from heavy cargo to more sensitive goods in both high cube and standard size containers.

N5 Container lashing System

This is a preassembled container lashing system to allow fast securing and easy handling. The system itself consists of two variable length ribbons to secure goods in different size containers against forward movement. The 2400mm long ribbon is for use in standard hight containers and the 2600mm long ribbon is used for high cube containers. These ribbons are anchored to the container at 4-points using hooks sewn onto the lashing ribbons connected to Fortris heavy duty pressed steel buckles for high strength. This system offers great security for shipments of goods traveling inside containers, as well as eliminating risks to workers when unloading the container by stopping goods falling out.

Accompanying products Dunnage Bags

Mega Fortris also offers paper and woven dunnage bags that can be used alongside lashing systems to secure goods against movement in transit. Dunnage bags can be used to assist lashing in stopping goods sliding, tilting or becoming unbalanced in transit depending on the load weight. Our paper dunnage bags contain a plastic inner layer to assure air tightness even in high pressures. The woven polypropylene dunnage bags are designed for securing heavy duty cargo in shipment and have an inner layer to assure air tightness in high pressures. The outer layer is highly resilient and resists most chemical solvents, bases and acids ideal for securing chemical shipments or goods from the utility industry.

Mega fortris offers many high-quality load securing solutions that can be used in tandem or alone to secure a wide range of heavy duty or potentially hazardous cargo. For more information and advice on the right solution for securing your goods find out more on our website or get in contact with our expert team.